Ready cranes, in the warehouse of the manufacturer. Warehouse cranes

— Old control cabin to a new one, as well as equipping the crane with a modern control system using a remote control from the floor or a radio remote control.

— An outdated crane control system to a new one based on frequency converters.

— Cargo trolley and its individual components: engine, brake, drum, hook suspension, movement mechanism, etc.

— Cable suspension.

— Chassis, as well as its various components and mechanisms: crane drive, rollers, etc.

Warehouse of materials. All purchased profile and sheet metal products are stored in the premises of the procurement and assembly and welding site. The material is stored on special racks in heated warehouses.

The shipment site. At this stage, labeling and shipment of finished products is carried out in accordance with technical requirements. The finished components and structures are shipped to our own vehicles, the rolling stock of which allows transporting large-sized structures up to 40 meters long.

In a completely isolated paint shop, shot blasting of metal is carried out on the PEM, Clemco line, in the PEM shot blasting chamber, there is also a sandblasting metal cleaning unit. At the painting site, the final preparation of surfaces for painting structures is carried out, followed by the application of an anticorrosive paint coating in a special chamber with SAMES KREMLIN equipment. The workshop is equipped with a rail trolley for the import and export of structures and two bridge cranes g/p 10 t. Materials used: two-component polyurethane primer and enamel.

The site of the control assembly and factory tests. After the welding and assembly work, the control assembly of the crane bridge and end beams is carried out, leveling, about which a pre-assembly protocol is drawn up, as well as all mechanisms pass factory tests idle without load, about which the corresponding protocols are also drawn up.

At the electrical installation site, work is carried out on the manufacture of equipment equipment and control cabinets, connection of equipment during testing of cranes, adjustment and adjustment of the parameters of the devices. The site is equipped with test stands and the necessary tools.

The assembly and welding section has three main slipways made with the use of special mounting plates: 66, 35 and 25 meters long. As well as two auxiliary slipways with a length of 25 meters with the use of wide-brimmed I-beams.

The mechanical section produces parts and components for the production of cranes. The use of modern metalworking equipment makes it possible to obtain high-quality parts with minimal dimensional tolerances. The machine park of the enterprise is represented by the following equipment: boring machines, milling machines, screw-cutting machines: CNC lathes (Haas, Knuth), drilling and special drilling machines, grinding and special grinding machines, band-cutting machines, stripping and grinding machines.

The procurement shop is equipped with ESAB gas-plasma sheet metal cutting machine, which has the ability to remove double-sided chamfers; ESAB portal cutting machine, two AURORA AIRFORCE plasma cutting machines, a CNC thermal cutting machine powered by SUPRAREX gas, VIMERCATI sheet bending press, HACO guillotine and other basic and auxiliary equipment necessary to ensure the main production of the workpiece without contacting third-party enterprises.

Duties

Design of lifting equipment

Requirements

— Higher technical education

— Reading blueprints

— Knowledge of 3D modeling programs: Kompas 3D (Autocad 3D, etc.),

— Knowledge of accounting software is a plus

— Understanding what GOST and Unified Design Documentation System

— Experience in mechanical engineering preferred

— Responsibility, discipline

Contacts

You can always get an answer to any question that arises by contacting the HR department:

Please send resume in one mail to:

info@npospeckran.ru

Leave a request

from 40 000 ₽

Semi-open cabs, closed cabs, modern cab “Diamond”.

Supporting steel structures, end beams, hooks, parts for production equipment (machines, conveyors), transfer trolleys, crane wheels.

Spreaders, traverses, magnets, grabs.

Suspension systems for cable current supply, electrical cabinets, cable trays, crane buffers, control panels and joysticks.

These are special overhead cranes with a jaw bucket that easily lift and transport bulk materials, scrap and shavings, coarse stone and fibrous materials, as well as long-length timber. Grab cranes have a grab winch with two drums, one of which is designed for winding the closing rope when the jaws are closed, and the other for winding the supporting rope (lifting). The lifting drum works together with the closing one when lifting and lowering the grab.

Bridge cranes are special cranes that are equipped with a magnetic gripping device. Such cranes are equipped with cargo electromagnets suspended on a hook suspension or traverse located in the longitudinal or transverse direction relative to the bridge. Due to this, the bridge magnetic crane performs specific operations with “iron” loads, attracting them and securely holding them with its electromagnetic devices. After removing the magnet, the crane can work as a hook. Magnetic grab cranes are designed for transshipment of ferromagnetic cargo (for example, cast iron, scrap, etc.), as well as bulk and lumpy cargo. An electromagnet is used to capture ferromagnetic cargoes, and a two-jaw grab is used for bulk cargoes. Depending on the purpose, they are carried out with two trolleys: magnetic and grab or with one trolley equipped with magnetic and grab winches.

A group of special overhead cranes used for the technological process in steelmaking workshops of metallurgical plants during the production and subsequent casting of steel. Cranes for the maintenance of spillway dams are designed to lift the gates of the upper and lower reaches, lift the gates of the water-retaining grilles, and also perform all the necessary set of auxiliary works for the repair and maintenance of the equipment of the dam construction itself.

Cranes used in the chemical industry are subject to requirements not only for explosion protection, but also for the durability of the materials used when working in aggressive environments containing acids, when working with alkali and chemical compounds. Incorrectly selected materials lead to severe corrosion and can cause subsequent expensive re-equipment.

Cranes that are placed in explosive zones both outside and inside the premises. Explosion-proof cranes (VZI cranes) are equipped with electric hoists and cargo carts, depending on the type of crane.

Special cranes used for transshipment of non-standard cargo. The traverses are box girders of constant, and with a large length — of variable cross-section, which are connected to the cargo trolley by means of a flexible or rigid suspension. Thanks to the traverses, it is possible to increase productivity, secure the work of personnel and avoid damage to the cargo during its movement. Also, traverses are used when lifting loads with height restrictions, allow transporting long loads without the impact of compressive and bending loads, automate the process of slinging cargo.

Special cranes that undergo particularly thorough acceptance, since any equipment in such Customer premises should not be a source of contamination.

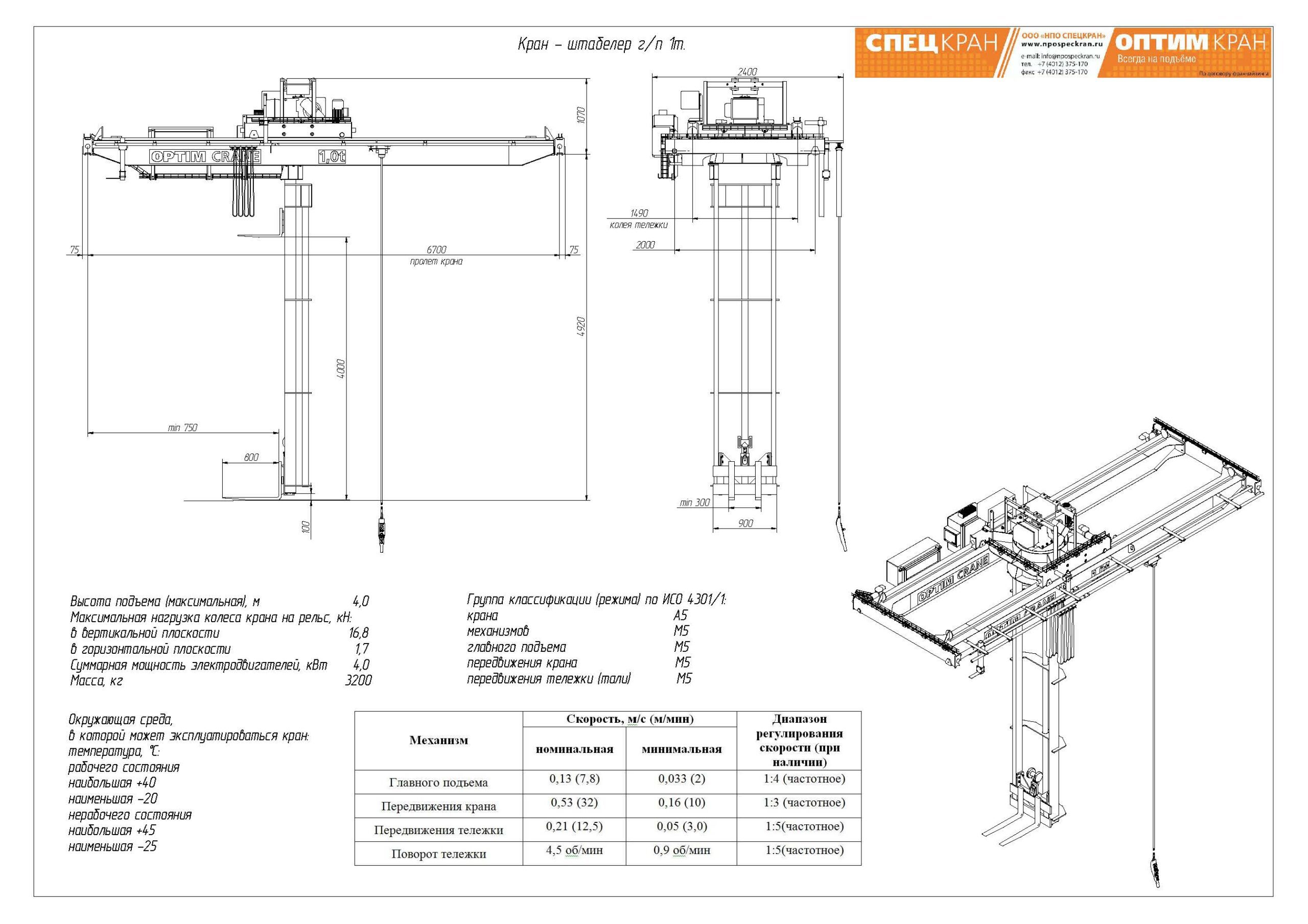

Stackers are a crane bridge on which a cargo trolley with a vertical column fixed to it, usually a rotary one, moves vertically along which a forklift (carriage) with a fork or special cargo grab moves vertically. The overhead stacker crane moves along rail crane tracks installed either directly on racks or on building structures. The crane can be supporting or suspended.

Special cranes of group A and group B, according to NP-043-11, moving irradiated nuclear fuel, highly enriched uranium, transuranic materials and (or) highly radioactive waste. The projects of such cranes are developed in accordance with the projects of the OIAE (facilities for the use of atomic energy) according to the technical specifications approved by the operating organization and the initial technical requirements for the design (design) of special cranes.

JSCO RUSSIAN RAILWAYS

More than one hundred trestle and bridge cranes with a lifting capacity of 5 to 32 tons were delivered to railway stations and car depots – from the central part of Russia to Sakhalin Island

Fabrication and delivery of 58 bridge cranes up to 25/5 tons and crane racks for Tikhvin Car Building Plant

Manufacture and supply of bridge cranes for Leningrad NPP – 2 and Belarusian NPP

Manufacturing and delivery of 56 bridge cranes for construction of new production for DSK-Grad, Moscow

For the company in the Republic of Guatemala

The delivery of 14 units of cranes, including grab cranes for work in the nickel mine, was successfully implemented

As part of the project for the construction of the casting and rolling complex in Tula

20 bridge double-beam special cranes from 10 t to 35/5 t were delivered and put into operation by the Plant.

Delivery of more than 80 complex special bridge cranes for metallurgy enterprises

Including those included in the OMK groups of companies – Vyksa, Chusovsky Metallurgical Plants, Magnitogorsk Metallurgical Plant

Special bridge cranes for pipe plants Such as Zagorsk pipe plant

Sinar pipe plant, Volzhsky pipe plant – more than 40 cranes manufactured and delivered

Manufacture and delivery of all major bridge cranes for the latest power facilities in Kaliningrad Oblast

(Regional Energy Security Program) – Mayakovskaya TPP, Talakhovskaya TPP, Pregolskaya TPP, Primorskaya TPP

For the metallurgical enterprise in the Republic of Cuba

Successfully delivered special cranes with a rotary trolley and special traversing cranes (participation in the program “Modernization and expansion of steel and long products production”)

More than 70 cranes of various capacity were manufactured, delivered and installed as part of the global renovation of the GPO fleet

At the largest machine-building plant in Yekaterinburg.

For energy facilities in the Republic of Uzbekistan, according to HPP modernization projects

Trestle and bridge cranes were supplied to such stations as the Farhad HPP, the Pskem HPP, the MHPP station at the Dargom Canal picket, and for the Russian Federation the plant manufactured cranes to the Verkhnebalkarskaya MHPP, Krasnogorsk MHPP, Barsuchkovskaya MHPP ES and Ust-Srednekanskaya HPP named after A.F. Dyakov.

Major project for the supply of GPO

Including container cranes for the new GOK under construction – implemented in 2022

Manufacture and delivery of bridge cranes of different capacity and complexity for our regular customers such as:

The machine-building enterprise «ELSIB», the largest manufacturer of equipment for quarrying equipment «Professional», the manufacturer of the most complex metal structures, including for the nuclear industry – the «Belenergomash-BZEM» plant, the KONAR industrial group, etc., is constantly going on.

We are always glad to new Customers, are open for negotiations and are ready to manufacture high-quality equipment for you in order to “take your company to the next level”!

Speckran’s activities are aimed at fully satisfying the interests of the Customer, including by expanding the range of manufactured equipment with special cranes – this is the main promising area of the company’s activities.

Our company, in the recent past, began working with nuclear industry enterprises, we also have experience in supplying container cranes. The company’s plans are to continue moving in these directions, as the most attractive from the point of view of new sales markets.

The motto of our technical department is unequivocally expressed in the words of technical director Yudanov Roman Viktorovich: “If a solution exists, then we will definitely find it!”

Semi-open cabs, closed cabs, modern cab «Diamond».

Supporting steel structures, end beams, hooks, parts for production equipment (machines, conveyors), transfer trolleys, crane wheels.

Spreaders, traverses, magnets, grabs.

Suspension systems for cable current supply, electrical cabinets, cable trays, crane buffers, control panels and joysticks.