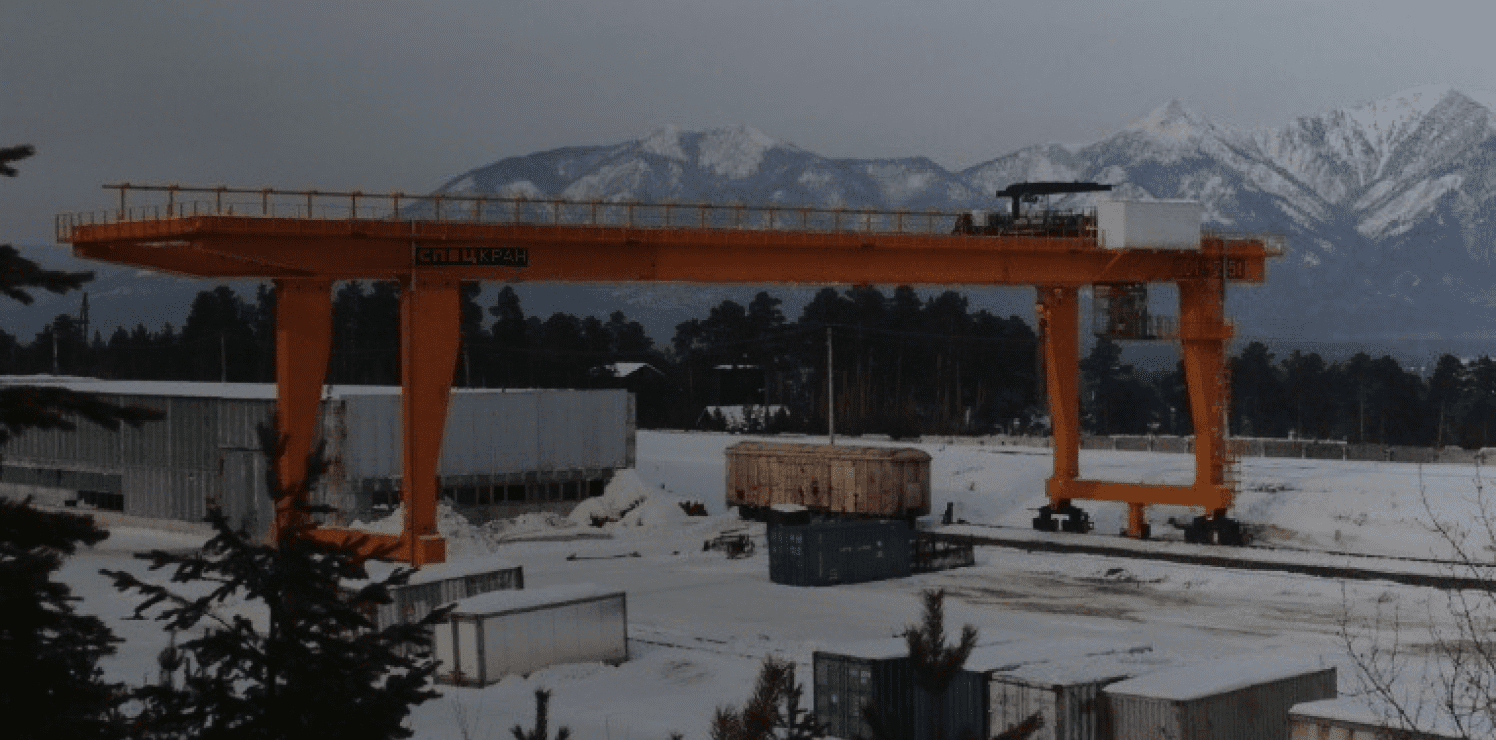

About cranes

Crane drive control based on modern frequency converters provides smooth, stepless regulation of all crane movements for accurate positioning and safety of goods.

The crane moves along the rail crane runway on four running bogies. Each of the carts is driven.

The undercarriage frame is a welded box structure. The location of the drive trolleys has a sufficient margin of adhesion of the driving wheels of the crane with the rail in any mode of loading the crane and regardless of the location of the cargo trolley relative to the bridge.

Additional options

- Operator panel with error output and up-to-date information on the crane

- Anti-swing system

- Centralized lubrication system

- Weighing system with visualization

| Gantry crane lifting capacity, t | from 5 to 200 |

| Span, m (L) | from 42 and more |

| Lifting height, m (H) | 6; 9; 12; 15; 18 and more |

| Speeds, m/min: Lifting load from 0.1 to 30 Cargo trolley movement from 20 to 60 Crane travels from 40 to 120 | from 0.1 to 30 from 20 to 60 from 40 to 120 |

| Gantry crane operating mode, according to ISO 4301/1 | А2…А8 |

| Operating mode of mechanisms, according to ISO 4301/1 | М3…М8 |

| Lifting device | Hook Spreader Traverse, magnet, grapple and etc. |

| Trestle crane control | Cabin Radio control Pendant |

| Drive control scheme | Frequency Relay Mixed |

| Climatic version | U1; U2; U3 |

| Conductor | Trolley Cable |

| Operating temperature range, °C | From -50 to +50 |

Fill out an application

Send the completed document to the mail:

or fill out the online form to receive our commercial offer.